Got Baskets? LeMatic Can Handle Them!

Industrial Basket Handling Systems for Commercial Bakeries

LeMatic’s basket handling systems are engineered to optimize the flow of product carriers throughout your bakery operation. Designed for speed, precision, and durability, these automated solutions reduce labor, improve safety, and streamline high-volume bakery production from start to finish. Whether you’re moving baskets between slicing, packaging, or cooling stations, our systems ensure consistent performance and dependable product handling every step of the way.

We offer a range of modular and fully integrated solutions for basket loading, unloading, stacking, unstacking, and conveying. Each system is custom-built to fit your production layout and throughput requirements—ensuring smooth, reliable basket transfers that keep your operation running efficiently. LeMatic’s equipment is designed for compatibility with various basket types, allowing for easy integration into both new and existing lines.

Our basket handling solutions are constructed with hygienic, easy-to-clean materials and minimal maintenance requirements, helping bakeries meet strict food safety and sanitation standards. These systems not only reduce repetitive manual tasks but also help eliminate bottlenecks, supporting better line balancing and faster overall production cycles.

With over 50 years of experience serving industrial bakeries, LeMatic brings the engineering expertise and automation innovation needed to elevate your bakery’s efficiency and performance. Explore our basket handling systems below to see how we can help you build a smarter, safer, and more productive operation.

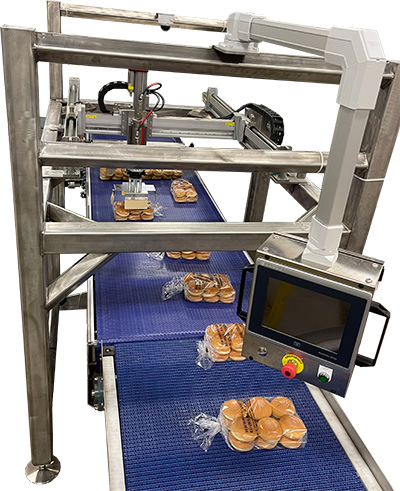

Pattern Former & Loader

Model P7

- Heavy-duty stainless steel frame

- High-Speed linear motors up to 70 packages per minute

- Auto iNet integrated

- Versatile design for new recipes/patterns entered at the HMI

- Quick-change tooling

Basket Loader

Model LBL-131

Accepts Variation in Basket Size and Style

- Microprocessor control on the LS132 Bulk Packer diagnoses problems on the LBL131 & communicates them to the operator for action

- Loads baskets in single or double pack style. Change-over only requires turning a switch

- Adjustable guide system accommodates variations of basket style & size