Aftermarket and Upgrades

Bakery Equipment Upgrades & Aftermarket Solutions

Maximize the performance and longevity of your bakery equipment with LeMatic’s industry-leading aftermarket upgrades and retrofitting solutions. Whether you’re looking to enhance productivity, reduce maintenance costs, improve safety, or bring older systems up to current production standards, our engineering and R&D teams deliver proven solutions tailored to your unique operation. LeMatic’s upgrades are designed to integrate seamlessly with both our own equipment and many competitor systems—offering a smart, cost-effective alternative to full equipment replacement.

Our aftermarket solutions include high-efficiency sealing systems, camera and DVR monitoring for remote visibility, independent hold-downs to manage lane pressure, and film spindle upgrades for faster roll changes. Each enhancement is engineered for durability, hygiene, and operational simplicity—allowing you to boost throughput and reduce downtime with minimal disruption to your existing line.

Retrofitting your bakery systems with modern components not only improves performance but also supports long-term sustainability initiatives. From energy-efficient sealing options like our Airless Band Seal to integrated productivity tools such as real-time video monitoring, LeMatic helps you modernize without sacrificing reliability.

We understand the demands of high-volume bakery operations and the need for flexible, scalable solutions. That’s why every aftermarket product we offer is designed to keep your lines running faster, cleaner, and more efficiently. Explore our innovative upgrades below to see how LeMatic can help you unlock more value from your bakery equipment investment.

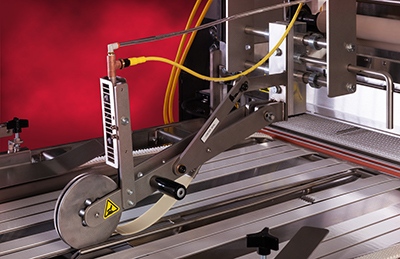

Cross SeaLeMatic

The Most Innovative Cross Sealing Technology Available

The new Cross SeaLeMatic lives up to its name being the most robust, reliable and simplified cross seal on the market today. It produces more sealing pressure, but it requires less air pressure! This decreases cycle time and enhances speed capabilities. The consumables are reduced and it requires less maintenance.

LeMatic Camera Systems

Fully Integrated Into Your Bakery Line

Monitor any bakery with LeMatic’s integrated Camera and DVR Systems that allow you to view locally from the plant or off-site and get real-time visibility. Or, with recordable video, look back in time to review operation history Adding a camera not only provides greater insight into line productivity, it saves valuable time and travel expenses.

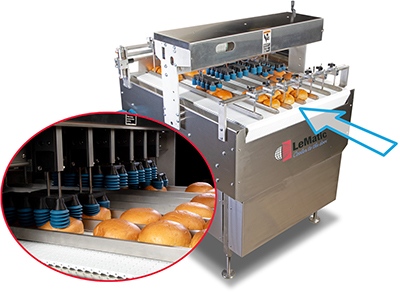

Independent Hold-Downs

Limits Product Lane Back Pressure

Plagued by lane back-ups and inaccurate product counts? LeMatic’s fully-adjustable Independent Hold-Downs keep a variety of products under control, avoiding costly down time on your slicing line. Additionally, they can be configured to any slicing machine, even our competitor’s.

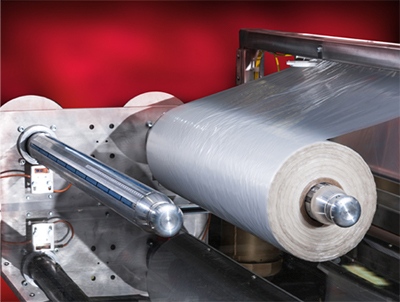

Pneumatic Film Spindles

Improved Roll Handling

Easier and more sanitary operation makes LeMatic’s Film Spindle upgrade a must-have for your high-capacity packaging system. Using your existing air supply, pneumatic film bladders inflate to keep rolls in place, and deflate for much easier roll replacement.

Seal & Cut Options

For Your Bulk Packaging System

LeMatic’s versatile Seal and Cut options allow you to separate most any bulk-packaged product into separate sealed sections, keeping unused product fresh and reducing product waste for the end-user. Talk to a LeMatic Sales Professional about the options available for your equipment.

Airless Band Seal

For Your Bulk Packaging System

LeMatic Airless Band Seals are a result of customer input and a calculated move toward sustainability initiatives.

Utilizing the latest technology available and our desire to provide the best sealed packages in the industry, LeMatic has added Airless Band Seals to our feature list on bulk packers. By implementing a continuous heated band through our newly designed side seal assemblies, clients can now run smooth seals in line with product (Side, Middle, Dual, Center) while not consuming compressed air.

LeMatic continues to focus on new innovation while supporting our equipment in operation around the world. With that focus, these units will be retrofittable to most all bulk packers already out there packaging for our customers.